How Long to Let Wood Dry After Pressure Washing: A Complete Guide

Introduction

Pressure washing is a fantastic way to revitalize wood surfaces, from decks to fences. However, ensuring proper drying time post-pressure washing is crucial to avoid issues like mold, mildew, or warping. In this comprehensive guide, we delve into the intricacies of how long you should let wood dry after pressure washing to achieve optimal results.

Understanding the Process

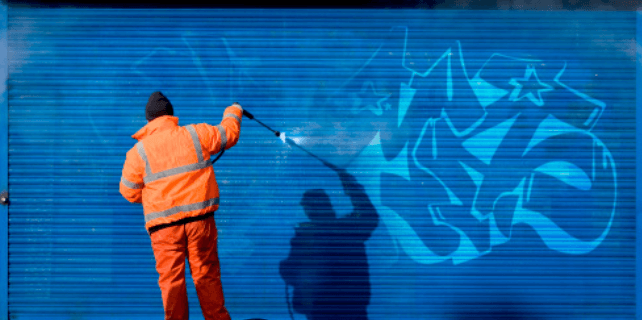

Explanation of Pressure Washing

Pressure washing is an effective method for rejuvenating various outdoor surfaces by utilizing a concentrated stream of water under high pressure. This powerful force efficiently dislodges stubborn dirt, mold, mildew, and other debris from materials like wood, concrete, and metal, resulting in a refreshed appearance. Moreover, pressure washing not only enhances the aesthetic appeal of surfaces such as decks, fences, and siding but also helps in maintaining their structural integrity, thereby extending their longevity.

Effects of Water on Wood

Wood possesses a porous structure, allowing it to absorb water readily. If not adequately dried, wood can undergo swelling, warping, and decay over time if exposed to excessive moisture. Additionally, the presence of high moisture levels creates a favorable environment for the growth of mold and mildew, exacerbating the deterioration of the wood and compromising its structural integrity.

Need for Drying After Pressure Washing

Drying wood after pressure washing is essential to remove excess moisture that could otherwise lead to decay and structural weakening. By allowing the wood to return to its original moisture content, it ensures its strength, stability, and longevity are maintained. This process not only safeguards against damage but also preserves the wood’s aesthetic appeal, ensuring it remains visually pleasing over time.

The Importance of Drying Wood After Pressure Washing

Pressure washing blasts away dirt, grime, and old finishes, leaving wood surfaces clean and ready for refinishing. However, moisture from the pressure washing process saturates the wood, necessitating adequate drying time before applying any sealants or stains.

Understanding Wood Moisture Content

Wood moisture content is a crucial determinant of its structural integrity and longevity, as excess moisture can instigate various forms of deterioration. When wood retains high levels of humidity, it becomes susceptible to rotting, warping, and fungal growth, compromising its stability and aesthetic appeal. Proper measures such as seasoning, kiln drying, or using moisture meters are essential to regulate and maintain optimal moisture levels in wood products, ensuring their durability and resilience against environmental factors.

Risks of Insufficient Drying Time

More drying time for wood surfaces poses a significant risk, as it can prevent the wood from reaching its optimal moisture content. When sealants or stains are applied before the wood has adequately dried, moisture can become trapped beneath the finish. This trapped moisture can cause the finish to fail prematurely and may also result in damage to the wood substrate over time, such as warping, cracking, or decay. Therefore, allowing sufficient drying time is crucial for ensuring the longevity and quality of the finish on wood surfaces.

Factors Influencing Drying Time

Several factors influence how long wood takes to dry after pressure washing. Understanding these variables can help you determine the appropriate drying duration for your project.

Type of Wood

The drying rate of wood is significantly influenced by its porosity and density, which differ across various types of wood. Hardwoods such as oak typically have a denser grain structure compared to softwoods like pine, resulting in a slower drying process. This variance in drying time is crucial to consider in woodworking and lumber industries to ensure proper moisture content and prevent issues like warping or cracking.

Severity of Contamination

The presence of dirt, grime, and other contaminants on a wood surface can significantly impact its drying time. When wood is heavily soiled, these substances can create barriers that hinder the evaporation of moisture, prolonging the drying process. Therefore, ensuring thorough cleaning and removal of contaminants is essential to expedite drying and prevent issues such as mold or warping.

Ambient Temperature and Humidity

Ambient conditions exert a crucial influence on wood’s drying process. In warmer and drier environments, the rate of moisture evaporation from the wood increases significantly, leading to faster drying times. Conversely, colder or more humid conditions can impede moisture evaporation, resulting in prolonged drying times for the wood.

Airflow and Ventilation

Proper airflow and ventilation play pivotal roles in facilitating efficient drying processes. Adequate ventilation permits the escape of moist air, thereby expediting the evaporation of moisture from the drying material. Conversely, stagnant air hampers moisture evaporation, prolonging the drying duration and potentially compromising the quality of the dried product.

Surface Area and Thickness

Thicker wood pieces and larger surface areas have greater moisture retention capacities, resulting in extended drying times compared to thinner pieces. To expedite the drying process, it’s crucial to maintain proper ventilation and airflow around the wood, facilitating the evaporation of moisture. Adequate airflow helps prevent the formation of mold and decay while ensuring a more efficient drying process overall.

Recommended Drying Times

General Guidelines

Allowing wood to dry completely before applying any treatments or finishes is crucial for ensuring optimal results and long-term durability. The drying time can vary depending on factors such as the type of wood, its moisture content, environmental conditions, and the size and thickness of the wood pieces. Generally, this process can take anywhere from a few days to several weeks, but patience is vital to achieving the best outcome.

Specific Drying Times for Different Types of Wood

Drying times for wood can vary based on the wood type and its initial moisture content. Hardwoods generally take longer to dry compared to softwoods due to their denser structure. Additionally, wood that is heavily contaminated, such as with excessive moisture or chemicals, may necessitate extended drying periods to ensure thorough evaporation and safe usage in various applications.

Considerations for Climate Variations

Climate variations significantly impact drying times, with factors such as seasonal changes and geographical location playing crucial roles. In humid climates, where moisture levels are high, wood may require a longer drying period compared to arid regions, where evaporation rates are higher. Careful consideration of environmental conditions is necessary for effective drying processes.

Methods to Speed Up Drying

Natural Drying Techniques

Natural drying techniques for wood involve optimizing airflow and sunlight exposure to enhance moisture evaporation. By stacking the wood in a location with ample ventilation and orienting it to catch sunlight, the drying process can be effectively accelerated. This method promotes the gradual removal of moisture from the wood, resulting in a more stable and usable material for various applications.

Use of Fans or Blowers

Fans or blowers are practical tools for expediting the drying process of wood by enhancing airflow across its surface. Strategically placing fans around the wood ensures that air circulates evenly, preventing moisture buildup and promoting uniform drying. Operating the fans on low settings minimizes the risk of causing damage to the wood while still maximizing the drying efficiency.

Application of Absorbent Materials

Due to their porous nature, absorbent materials like sawdust or kitty litter are effective in extracting moisture from wood. When sprinkled onto the wood’s surface, these materials act as sponges, drawing out excess moisture and accelerating the drying process. This method is beneficial for damp wood, as it helps prevent warping, mold growth, and other issues associated with prolonged moisture exposure.

Importance of Proper Drying

Prevention of Mold and Mildew Growth

Proper drying is essential as it mitigates the conditions conducive to the growth of mold and mildew, which thrive in damp environments. By effectively removing excess moisture from the wood, drying significantly reduces the risk of microbial infestation, safeguarding both the structural integrity and the health of the wood. This process not only preserves the wood’s quality but also ensures longevity, making it less susceptible to decay and damage caused by fungal growth.

Preservation of Wood Quality and Integrity

Thorough drying of wood is essential for maintaining its quality and integrity over time. By ensuring the wood remains potent, stable, and free from damage, its lifespan is significantly prolonged. This not only minimizes the need for costly repairs or replacements but also ensures that the wood retains its structural integrity, making it a valuable and sustainable material for various applications.

Preparation for Subsequent Treatments or Finishes

Adequately dried wood is essential for achieving optimal results when applying treatments or finishes such as stains, paints, or sealants. The absence of excess moisture ensures better adhesion and penetration of these products into the wood fibers, leading to a more uniform and durable finish. Additionally, thoroughly dried wood reduces the risk of issues like warping, cracking, or peeling that can occur when moisture is trapped beneath the surface.

FAQs (Frequently Asked Questions)

How long should I wait to seal the wood after pressure washing?

Allow the wood to dry for a minimum of 24 to 48 hours before applying any sealants or stains. Ensure the wood’s moisture content is within the recommended range for optimal results.

Can I speed up the wood drying process after pressure washing?

Yes, you can accelerate drying by increasing airflow and ventilation around the wood surface. Utilize fans or dehumidifiers to expedite moisture evaporation.

What happens if I don’t let wood dry after pressure washing?

Failing to let wood dry adequately after pressure washing can lead to a host of issues, including mold growth, rotting, and premature failure of sealants or stains.

Is it necessary to sand wood after pressure washing?

Sanding may be required to smooth out any raised wood fibers or imperfections caused by pressure washing. However, to avoid damaging the surface, ensure the wood is completely dry before sanding.

Can I apply the stain immediately after pressure washing?

It’s essential to allow the wood to dry thoroughly before applying any stains or sealants. Rushing the process can trap moisture within the wood, leading to unsightly blotching or adhesion issues.

Should I pressure wash the wood before staining?

Yes, pressure washing effectively removes dirt, grime, and old finishes, creating a clean surface for staining. However, ensure proper drying time before proceeding with staining to achieve the best results.

Conclusion

Understanding the optimal drying time for wood after pressure washing is crucial to prevent damage and maintain its quality. Factors such as wood type, weather conditions, and the extent of moisture penetration all influence how long it takes for the wood to dry completely. By adhering to the recommended drying guidelines provided in this article and considering these influencing factors, you can achieve desirable results for your pressure washing endeavors. Ultimately, allowing sufficient drying time ensures the integrity and appearance of your wood surfaces are preserved, leading to successful and long-lasting outcomes for your projects.

Remember: A clean house is a happy house!